Product Description

Steel nozzles of powerful sand blasters wear down during one working day, whereas sapphire nozzles serve up to 30 working days. Water-jet cutting is one of the modern techniques for cutting ceramics, solid alloys, rocks, and dangerous articles such as nuclear warheads, military rockets, and gas containers.

The quality of cutting and the productivity of hydraulic monitors depend upon nozzle size stability. In a number of cases sapphire jet-forming nozzles successfully substitute their hard-alloy analogs.

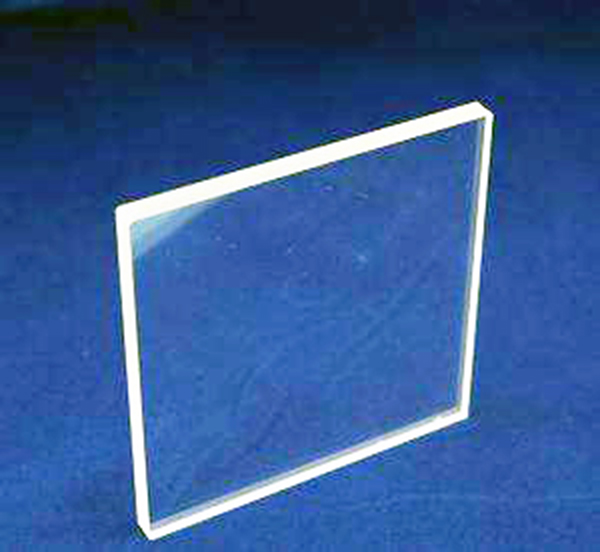

Sapphire could be used as windows: 1.mobile phone screens; 2. lens; 3. fingerprint recognition; 4. Wearable equipment windows and so on, because of its unique advantages including: high sensitivity, scratch resistance, abrasion resistance, high temperature resistance, high pressure resistance, good chemical stability, and corrosion and deliquescence resistance.

CONTACT US

ShanXiZhongJuJingKe Semiconductor Co., Ltd

Contact Person: yang

Phone:86-0354-3051057

Fax:

Address: No.2, machinery park, huitong industrial park, jinzhong development zone, shanxi demonstration zone,Jinzhong,Shanxi